Selecting the Right Plate Magnet for Luminex Assays

With the introduction of MagPlex® beads, more streamlined protocols can be developed for protein and nucleic acid applications.

With magnetic beads, high throughput experiments being done in 96 well plates or higher formats no longer need to have washing and other buffer exchange steps done by spinning plates or washing beads with filter plates. Such steps increase processing times, prevent developing automated protocols, and contribute to bead loss and higher CVs. By switching MicroPlex® bead assays to MagPlex® beads, protocol times can be shortened, and lower bead loss generates more reliable and reproducible data.

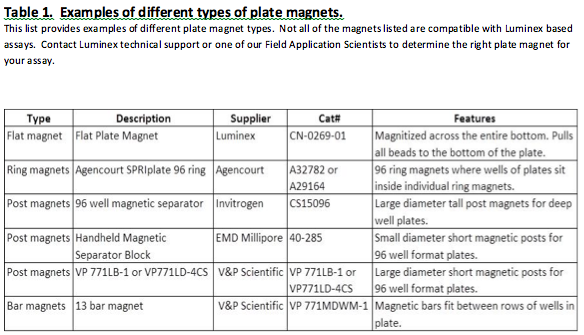

Because a large number of different plate magnet designs are available, selection of the right plate magnet is critical to maximize the advantages of using MagPlex® beads. Four different plate magnets designs include 1) flat plate magnets, 2) bar magnets, 3) post magnets, and 4) Ring magnets (Table 1). Several factors need to be considered to determine which magnet design fits your needs best. One of the first factors to consider is the type of assay it is used for, a protein based assay or nucleic acid assay with PCR steps and/or heated reading.

Many protein-based assays can be done in flat bottom microtiter plates and processed manually with or without plate washers. These types of assays can use flat plate magnets—where the entire bottom of the magnet is magnetized. While this type of magnet may be suitable for low sample number experiments processed manually, higher throughput experiments employing more automated handling may require a shift to bar-, post-, or ring-type magnets—especially when they need to shift away from flat bottom plates and need plates with conical or curved wells. In this case, several other factors similar to those required for nucleic acid assays need to be considered as described below.

Most nucleic acid assays—especially those with PCR steps—can be processed manually or with semi-automated protocols. Due to the sensitivity of the PCR steps, it is crucial to prevent cross contamination between wells on the plate. As a result, whether using a manual processing protocol or automated protocol, disposable tips are required to eliminate any cross contamination between wells on the plates. In addition, the need to run reactions in a thermal cycler or analyze in the Luminex heater block requires the use of PCR plates with conical shaped wells.

During different steps in the protocols and during washing steps, these assay characteristics require the complete removal of buffers from the wells with minimal bead loss. This requires a magnet design that will pull the beads to the sides of the wells so that pipette tips can go all the way to the bottom for complete removal of reaction buffers. For PCR-based nucleic acid assays and high throughput protein assays employing conical well plates, the two following factors must to be considered.

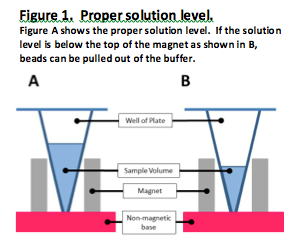

- At any step in the protocol when the magnet is needed and the plate fits securely on the magnet, is the reaction volume large enough that the top of the solution is above the top of the magnet? If the top of the solution is below the top of the magnet, beads can be pulled out of the solution, dramatically altering the reliability of the assay (Figure 1).

- Is the magnet strong enough to pull the beads out of the way in a short period of time? Reaction solutions can have different viscosities and will require different strength magnets. So the strongest magnet that also meets the needs of requirement 1 above will be the preferred magnet—especially if it can clear the solution of beads within 2 minutes or less.

So whether you are designing a multiplex proteomic assay or nucleic acid assay, keep these guidelines in mind when selecting a plate magnet. If you need further recommendations for the best magnet for your specific Luminex application, contact Luminex technical support or your Field Application Scientist for more information.