Inside xMAP INTELLIFLEX®: Design & Engineering Team

By Gabby Mora

The xMAP INTELLIFLEX® is our newest xMAP® Technology platform, and it enables scientists to generate even more data from each reaction. We have created a dedicated team to support customers using this system, and in this blog series, we’re getting to know some of those team members for a closer look “Inside xMAP INTELLIFLEX®.”

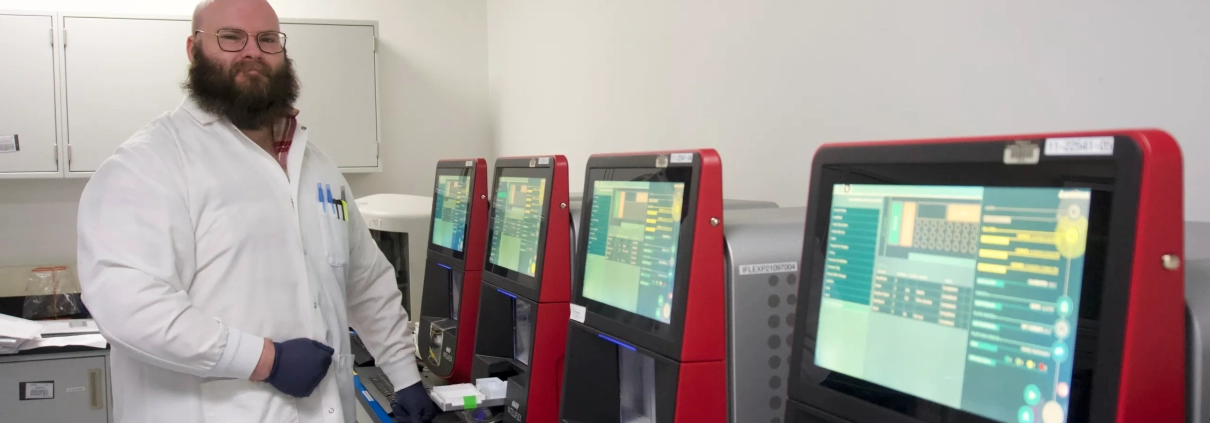

First, we’ll introduce you to a few people on the design, transfer, and process engineering (DTPE) team, which includes manufacturing engineer and scientist Andrew Jameson and senior manufacturing engineer Safaa Rubeaay.

Q: What are your responsibilities at Luminex?

Andrew: We’re a bridge between R&D and manufacturing. R&D creates the instrument designs, and we ensure we can bring them into manufacturing in a way that can be successfully executed. We also incorporate process engineering if a problem arises and if we need to identify and address the root cause.

Q: How does DTPE contribute to the xMAP INTELLIFLEX team?

Andrew: The xMAP INTELLIFLEX System is a combination of machine plus xMAP® Technology, and my work involves the reagent side. Our users should have confidence that their results are reliable and actionable, and we work to ensure that happens.

Safaa: I’m the manufacturing engineer for the whole line, so my responsibilities include monitoring the process of the build and debugging any issue within the xMAP INTELLIFLEX System, from beginning to end. I’m also the point of contact for any issues that might arise in the field, and I help troubleshoot whether we need to change a part, change the design, add a new kit, or something else.

Q: How does DTPE drive improvements for the xMAP INTELLIFLEX System?

Andrew: We are essentially the very first customers of the xMAP INTELLIFLEX System, as we run it daily and perform checks in the software, user interface, or any other element involving the system on a day-to-day basis. If we find something that doesn’t work as well as we’d like, we direct that back to our development group to see how it can be addressed.

Safaa: I work with our suppliers to control the elements and components within the device when we acquire new software, which sometimes requires changing parts or implementing the new software within a component. Our team also tests and implements any changes and follows up to see how everything functions in the field.

Q: What’s your favorite thing about the xMAP INTELLIFLEX System?

Andrew: I like the UI (user interface) design and the general design philosophy that’s gone into it which makes it more internationally usable. This system is less reliant on text and has easy-to-read button functionality and menu setup.

Safaa: This is a great device that will save users lots of time. You can run tests for so many different things with one click and get so much information to analyze from each sample.

Learn how xMAP INTELLIFLEX can help streamline your workflow and optimize your data analysis

For a deeper dive into unique system features and how other researchers are tapping into the technology, check out these resources:

- White Paper: Dual Reporter Functionality of the xMAP INTELLIFLEX® DR-SE System

Read now >> - JoVE Open Access Publication & Video: Beyond Checkpoint Inhibitors: New Cancer Vaccine Candidate Shows Promising Preclinical Results (The Ohio State University)

Get open access >> - JoVE Open Access Publication & Video: NMI Researchers Choose xMAP® Technology to Identify Exposure to Lyme Disease Causing Pathogens

Get open access >>